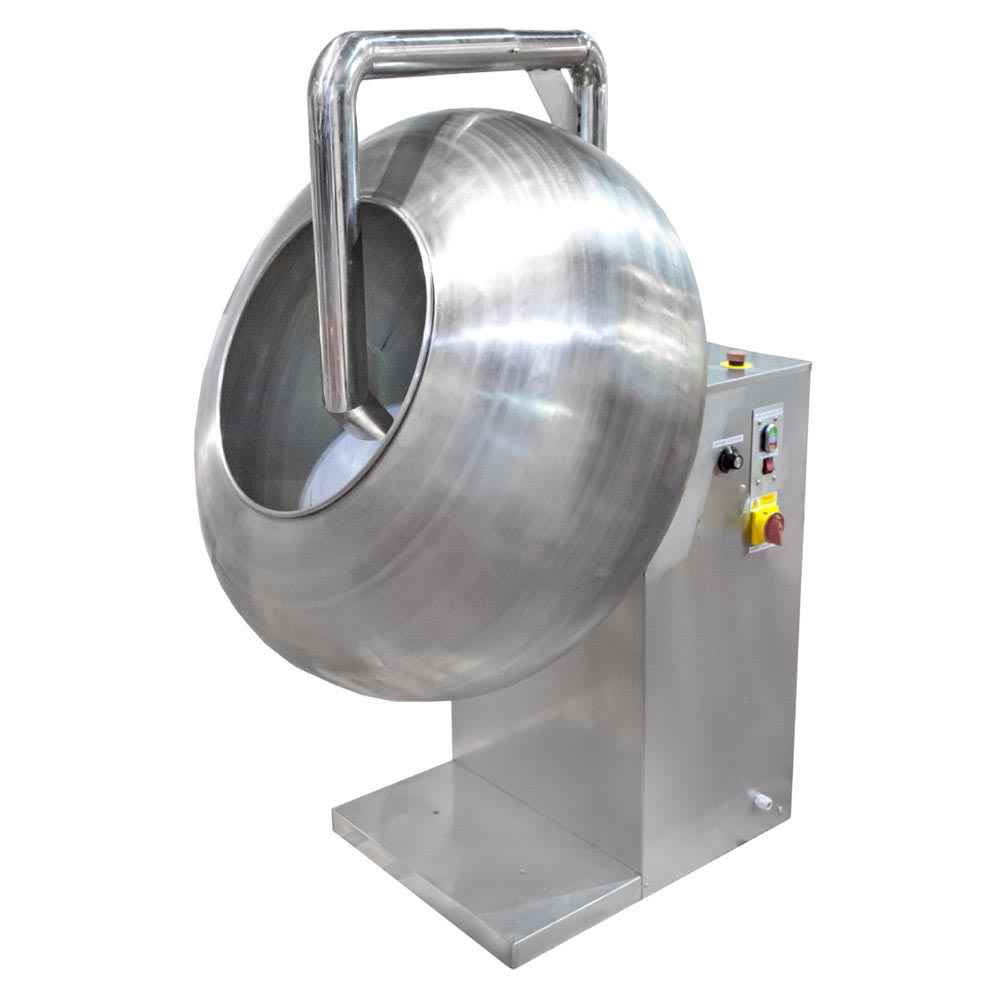

Chocolate Coating Machine Chocolate Panning Machine

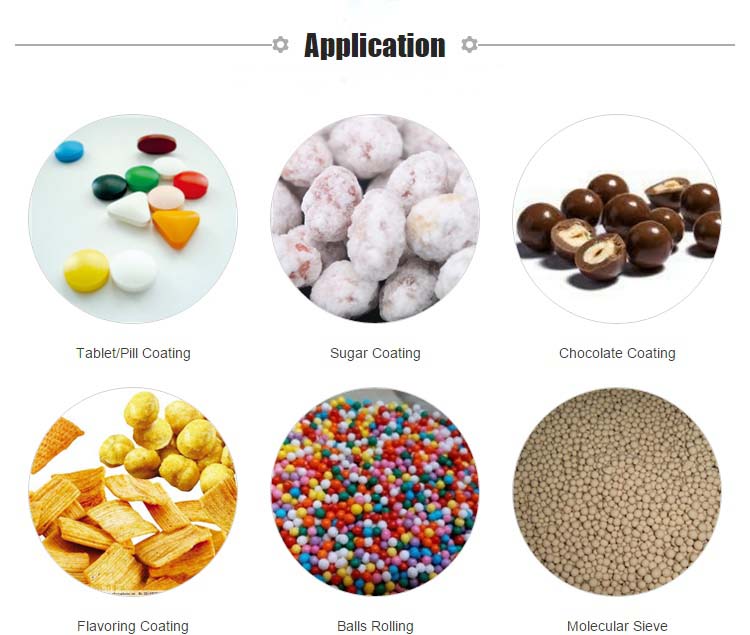

This machine is used in the pharmaceutical and food industries for the coating of sugar-coated tablets and pills. It can also be used as a fried bean and fruit. Its characteristic is that the tilt angle of the sugar-coated pot is adjustable, and direct heating equipment such as electric furnace and gas can be placed under the pot. A separate electric heating blower is attached, and the air outlet pipe (adjustable air volume) can be heated or blown into the pot. 2 heat (temperature) can be adjusted. 3 main engine speed control motor is adjustable.

- 1. This chocolate panning machine used to coating the tablets and pills for pharmaceutical and food industry.

- 2. chocolate panning machine is used for rolling and heating beans and edible nuts or seeds.

- 3. chocolate panning machine can be used to polish chocolates of various shapes such as cylinders, oblatenesses to make their surfaces well lustrous and colored.

|

name |

ABF--T500A |

ABF-T1250A |

|

Sugar-coated pot diameter |

500 |

1250 |

|

Sugar pan speed |

0-50 |

30 |

|

Main motor power |

0.55 |

2.2 |

|

Blower power |

0.04 |

0.25 |

|

Production capacity |

10 |

90-150 |

|

Dimensions (length × width × height) |

530×630×850 |

1200×1250×1630 |

|

weight |

95 |

280 |

Pre-sale

1.Confirm machine type: Negotiate with clients to seclect the correct machine according to customers’ requirment.

2.Quote and Sign firm contract: After confirm with customers with all details, such as payment terms, model, delivery time, send official quotation to clients.

After-sale

1.When equipments arrive in clients factory,send engineers there for installation and ensure customers know how to operate the machine.

2.In order to improve our products,we keep in close contact with customers to know their feedbacks and suggestions.

3.From the date of the buyer receive the machines, free warrant for 12 months.

Packaging and Delivery

1. Prompt deliver at the very day.

2. Sophisticated and professional logistic agent.

3. Well-trained and disciplined packing team.

4. After-sale service:. Any questions or problems after receiving the product,

please feel free to contact us. Problems would be solved for you immediately.

Quality Guarantee

The quality of the production line will have 12 month warranty since the installtion in the buyer's factory.

• Top Food machine manufacturer in China

• 20000 square meters production plants

• Over 22 years of experience

• Made-in-China’s Gold member since 2009

• CE, ISO9001

certified

• Engineers able to offer overseas installation

and testing, and training.The plant

layout design, assembling, installation and debugging, start-up and local team

training will be FREE at no cost.

• Prompt delivery and flexible payment terms

• Small order is welcomed

• professinal team with strong technical and

R&D knowledge to develop advanced food equipments

• save labor cost and improve the capacity.

Structure of chocolate panning machine :

As its feature, the chocolate panning machine whose round pot is elevated, the heater such as gas electrical heater can placed directly under the pot. A separated blower with electrical heater is provided with the machine. The pipe of the blower stretches into the pot for heating of cooling purpose. The thermal capacity of this nuts sugar coating machine is adjustable.

Structure of chocolate panning machine :

As its feature, the chocolate panning machine whose round pot is elevated, the heater such as gas electrical heater can placed directly under the pot. A separated blower with electrical heater is provided with the machine. The pipe of the blower stretches into the pot for heating of cooling purpose. The thermal capacity of this nuts sugar coating machine is adjustable.

Features of Peanut Chocolate Coating Machine

The machine is simple, easy to operate, smooth, bright, delicate, saves material, and it is simple to maintain.

Introduction of Chocolate Peanut Coating Machine:

- ♦This machine has strong/feebleness electricity, hydraulic, pneumatic in set in interation, to transform the original ordinary coating machine of new equipment.

- ♦Mainly by the host (the original coating machine), controllable temperature hot air system, automatic spray system for liquid gas supply and other parts.

- ♦Main motor frequency control of motor speed, it is the electrical automatic control method of coating materials with high atomized spray gun to pill on the surface, and make continuous tablets in the coating pan complex trajectory, the coating liquid evenly package on the slice of core tablets, pan with controllable temperature hot air to dry tablets at the same time, the pill rapid formation on the surface of hard, and it makes the surface of the film fine, full, smooth.

Stainless Steel Automatic Pill Almond Nuts Sugar Popcorn Candy Coating Pan Small Peanut Chocolate Coating Machine Price , Stainless Steel Flavor Spray Peanut Coating Machine

Products

- 500L double arm sigma blade kneader mixer

- 1000L Sigma Mixer

- Double Sigma Arm Mixer Machine

- High Viscosity Screw Extruder Double Sigma Blade Kneader Mixer

- Hot Melt Adhesive Sigma MixerDough Sigma Blade KneaderZ Blade Kneader MachineChewing Gum And Bubble Gum Kneader Machine

- Softgel Capsule Manufacturing Equipments

- Silicone Rubber Sigma Blade Mixer

- Hot Melt Adhesive Sigma Mixer

- High Viscosity Screw Extruder Double Sigma Blade Kneader Mixer

- Gelatin Cooking Mixer Manufacturer

- Softgel Capsule Manufacturing Equipments

- Gelatin Cooking Mixer Manufacturer

- Gelatin Holding Tank

- Reaction Vessel

- V Cone Blender Mixer

- Condenser / Heat Exchanger

- Pressure Vessels

- Distillation Unit

- Pilot Reaction Unit

- Sigma Mixer

- Ribbon Blender

- ETO Sterilizer Machine

- Ethylene Oxide Sterilizer

- ETO Sterilizer for Hospital

- Cath lab ETo Sterilizer

- Horizontal Autoclave

- Cylindrical Autoclave

- Eto Sterilizer Exporter in India

- Reaction Vessel Exporter in India

- sigma mixer manufacturer